Harnessing the Power of the Connected Enterprise: Reducing Human Error to Drive Growth

In the fast-paced landscape of modern business, the concept of the connected enterprise has emerged as a transformative force. A connected enterprise integrates advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), cloud computing, and data analytics to create a cohesive ecosystem where information flows seamlessly across departments and functions. This connectivity not only enhances operational efficiency and agility but also plays a crucial role in mitigating human error—a persistent challenge that can impede growth and competitiveness.

<> Understanding Human Error in Business

Human error is an inherent aspect of any organization where people interact with complex systems, processes, and technologies. From data entry mistakes and miscommunication to operational lapses and decision-making errors, human errors can have far-reaching consequences. These errors not only disrupt workflows but also lead to financial losses, compromised customer satisfaction, regulatory non-compliance, and reputational damage. In industries such as healthcare, finance, manufacturing, and logistics, where precision and reliability are paramount, even minor errors can result in significant repercussions

Errors in data entry, inventory management, or scheduling can lead to inefficiencies, delays, and increased operational costs.

Mistakes in order processing, billing, or customer support can result in dissatisfaction, erosion of customer trust, and churn.

#1. Technological Foundations of the Connected Enterprise

At the heart of the connected enterprise are advanced technologies that facilitate seamless communication, collaboration, and decision-making across organizational hierarchies and geographical boundaries

Internet of Things (IoT): IoT devices collect real-time data from interconnected sensors, machinery, and equipment. This data provides insights into operational performance, maintenance needs, and resource utilization, reducing reliance on manual data entry and minimizing errors associated with human intervention.

Artificial Intelligence (AI): AI-powered algorithms analyze vast amounts of data to identify patterns, anomalies, and predictive insights. Machine learning algorithms can automate routine tasks, detect errors in data processing, and optimize decision-making processes, reducing human error and enhancing operational efficiency.

Cloud Computing: Cloud-based platforms provide scalable infrastructure and secure data storage solutions. Centralized data repositories and real-time collaboration tools enable seamless information sharing, ensuring accuracy and consistency in data-driven decision-making across departments.

Data Analytics and Visualization: Advanced analytics tools transform raw data into actionable insights through interactive dashboards and visualizations. Data-driven insights empower stakeholders to make informed decisions, detect potential errors proactively, and optimize business processes for efficiency and growth.

Cybersecurity and Data Protection: As organizations embrace digital transformation, cybersecurity measures safeguard sensitive information from unauthorized access, data breaches, and cyber threats. Robust cybersecurity frameworks ensure data integrity, compliance with regulatory standards, and trust among stakeholders.

#2. Mitigating Human Error through Connected Enterprise Strategies

The connected enterprise leverages technological innovations to mitigate human error and drive growth across key business functions:

Automated Data Capture and Processing: IoT sensors and connected devices automate data capture processes, reducing reliance on manual data entry and minimizing transcription errors. Real-time data analytics identify discrepancies and anomalies, enabling timely corrective actions and improving data accuracy.

Streamlined Workflow Automation: AI-driven workflow automation tools streamline routine tasks, approvals, and document management processes. Automated workflows reduce administrative burdens, standardize operational procedures, and minimize errors associated with manual intervention.

Predictive Maintenance and Asset Management: IoT-enabled predictive maintenance systems monitor equipment performance, detect potential failures, and schedule proactive maintenance activities. Predictive analytics optimize asset lifecycle management, minimize downtime, and ensure operational continuity.

Enhanced Supply Chain Visibility: IoT sensors and blockchain technology provide end-to-end supply chain visibility, tracking inventory levels, shipment status, and delivery schedules in real time. Enhanced transparency reduces supply chain disruptions, improves order fulfillment accuracy, and enhances customer satisfaction.

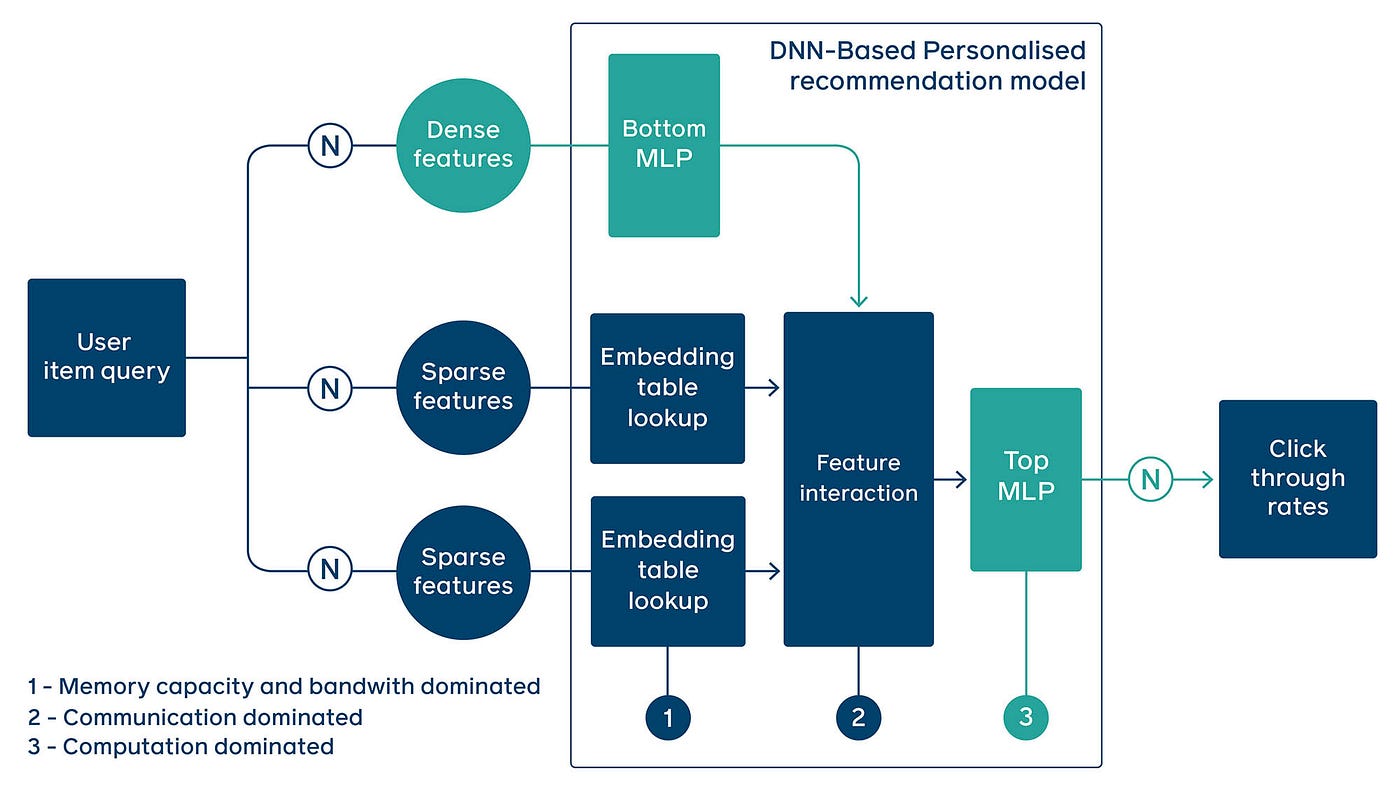

Personalized Customer Interactions: AI-powered customer relationship management (CRM) systems analyze customer data to personalize marketing campaigns, recommend products, and anticipate customer preferences. Personalized interactions foster customer loyalty, increase conversion rates, and mitigate errors in customer communications.

Continuous Learning and Development: The connected enterprise invests in employee training programs and professional development initiatives. E-learning platforms, virtual simulations, and AI-powered training modules enhance employee skills, promote adherence to best practices, and mitigate errors through continuous learning.

Integrated Risk Management Frameworks: AI-driven risk management platforms analyze market trends, regulatory changes, and financial indicators to assess risk exposure and develop proactive mitigation strategies. Integrated risk management frameworks enhance organizational resilience, ensure regulatory compliance, and safeguard against errors in risk assessment and decision-making.

Healthcare Industry: Connected medical devices and telehealth platforms improve patient monitoring, diagnosis, and treatment. AI-powered diagnostic tools analyze medical imaging data to detect anomalies, reduce diagnostic errors, and optimize treatment outcomes.

Manufacturing Sector: IoT-enabled smart factories automate production processes, monitor equipment performance, and optimize resource allocation. Predictive maintenance systems reduce downtime, enhance operational efficiency, and minimize errors in manufacturing operations

#3. Challenges and Considerations in Implementing a Connected Enterprise

Technological Integration: Integrating disparate systems, legacy infrastructure, and third-party applications requires interoperability standards, API integration, and data synchronization protocols..

Retail and E-commerce: AI-powered recommendation engines personalize product recommendations, optimize pricing strategies, and enhance customer shopping experiences. Integrated inventory management systems minimize stockouts, improve order accuracy, and streamline supply chain operations.